By Louis ‘Barok‘ C. Biraogo — April 18, 2025

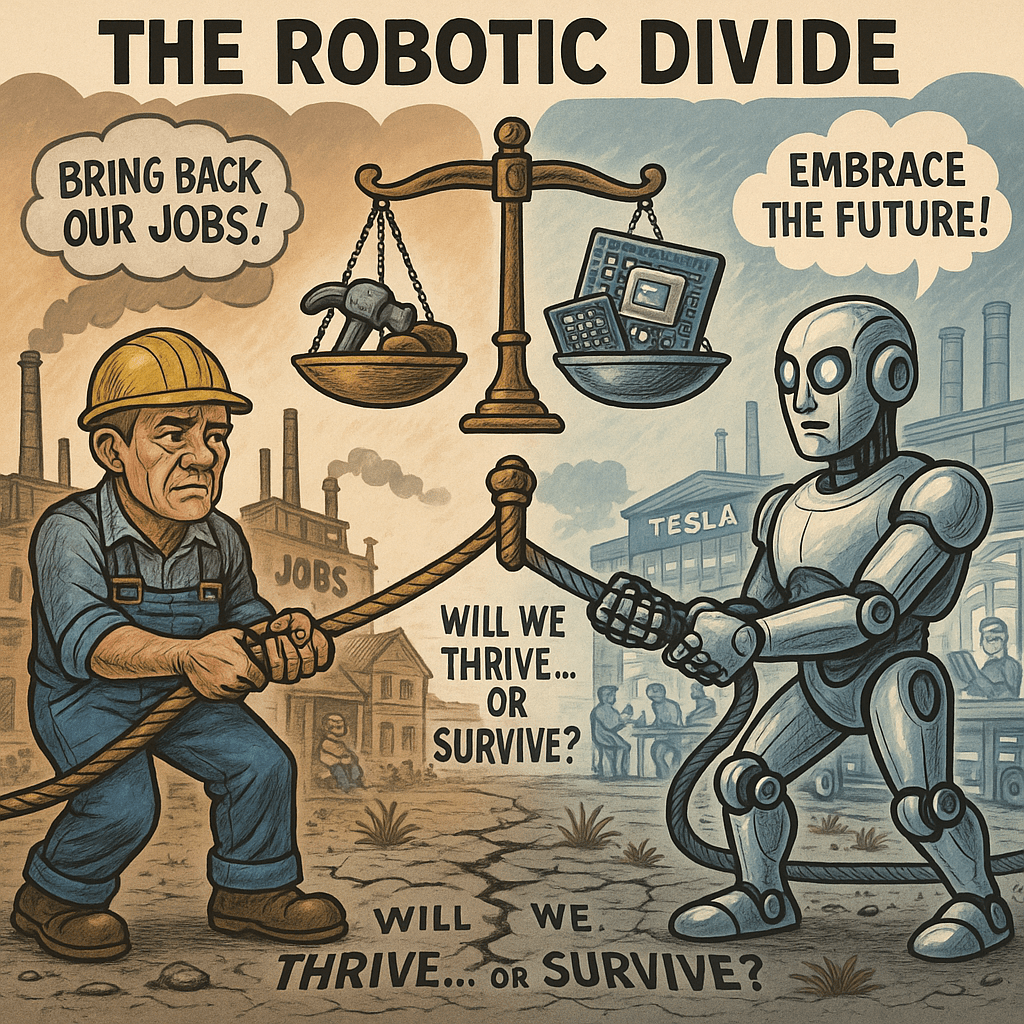

YOUNGSTOWN, Ohio, smells like rust and regret. The corpse of a steel mill stands frozen in time, its parking lot a graveyard of cracked asphalt and thistles. Meanwhile, 1,200 miles south, Tesla’s Gigafactory pulses with the sterile rhythm of machines building the future—no workers needed. This is America’s manufacturing paradox: They mourn the death of factory towns but refuse the jobs that kept them alive. Now, as robots rise, one question remains: Will they resurrect the heartland, or bury it for good?

The Great American Contradiction: Loving Factories, Hating the Grind

Americans are clear: 80% believe more manufacturing jobs would strengthen the nation, according to a 2024 Cato Institute survey. Yet only 25% say they’d personally benefit from working in a factory, and a mere 2% do. This isn’t just hypocrisy—it’s a cultural and economic disconnect. Manufacturing jobs, once the backbone of the middle class, now carry a stigma of grueling hours and meager rewards. Only 36% of young Americans (18–29) express interest in these roles, per Cato, despite nearly 500,000 unfilled positions reported by the St. Louis Federal Reserve in April 2025.

Why the aversion? Pew Research offers a clue: Manufacturing workers report “markedly” lower satisfaction than their peers, with just 35% content with their pay (vs. 41% overall), 40% with benefits, and 45% with work-hour flexibility. The cultural narrative doesn’t help. Factories evoke images of repetitive toil, not the high-tech promise of Silicon Valley. Meanwhile, globalization’s toll—decimated industrial towns, soaring inequality (a Gini coefficient of 0.41)—fuels nostalgia for a manufacturing golden age that fewer and fewer want to inhabit.

This paradox isn’t abstract. It’s the anxiety of 62% of middle-income Americans who, per Primerica’s Q1 2025 Financial Security Monitor, stress over finances, with 46% expecting to be worse off next year. It’s the shuttered plants in places like Marion, Ohio, and the unfulfilled promises of politicians who vow to bring them back.

Robots to the Rescue? A High-Tech Salvation or Job-Slaying Menace?

Could robots resolve this tension? The case is compelling, but the risks are steep.

The Promise: Filling Voids, Redefining Work, Winning Globally

Robotics could address America’s manufacturing woes head-on.

- Filling labor shortages: With 500,000 open jobs and only 25% of Americans willing to take them, robots are already stepping in. In 2023, the U.S. installed 41,000 industrial robots, a 14% jump from 2022, per the International Federation of Robotics. Tesla’s Gigafactory, with over 1,000 robots, shows how automation can scale production without relying on reluctant workers.

- Rebranding manufacturing as high-tech: By automating repetitive tasks—welding, packaging, assembly—workers can shift to roles like robot programming or maintenance, which pay $60,000–$80,000 annually compared to $40,000 for assembly line jobs (BLS, 2023). This aligns with Pew’s findings on dissatisfaction, offering better pay and flexibility. It could also lure younger workers, who crave tech-driven careers over “screwing in little screws,” as Commerce Secretary Howard Lutnick put it.

- Bolstering global competitiveness: U.S. labor costs are five times China’s (BLS, 2023), and tariffs, like those from Trump’s first term, added $40 billion in annual costs without creating jobs, per the National Bureau of Economic Research. Robots boost productivity—since 2000, automation has lifted manufacturing output 30% despite a 20% job drop (Federal Reserve, 2024)—allowing the U.S. to offset tariff-driven price hikes and reduce reliance on imports, which account for 15% of goods, per Goldman Sachs.

The Peril: Widening Inequality, Jobless Towns, and Import Quagmires

But the robotic revolution isn’t a panacea.

- Job displacement: MIT’s David Autor and colleagues found that from 1990 to 2010, automation displaced 1.5 million manufacturing jobs, hitting low-skill workers hardest. Rapid robot adoption could exacerbate this, especially in Rust Belt towns already scarred by decades of decline. Without retraining, displaced workers face unemployment or low-wage service jobs, deepening inequality and fueling the financial anxiety gripping 62% of the middle class.

- Import dependence: Many robot components—sensors, chips—come from Asia, per Goldman Sachs. Tariffs could raise automation costs, slowing adoption, while global chip shortages, like those in 2021–2023, expose supply chain vulnerabilities. If the U.S. leans too heavily on robots without building domestic production, it risks swapping one form of import reliance for another.

- Social resistance: Automation may clash with the human-centric rhetoric of Trump’s reshoring agenda, which promises jobs for “fired federal workers,” per Treasury Secretary Scott Bessent. Unions, like the UAW in their 2023 strikes, already demand protections against automation. Rural communities, wary of Silicon Valley’s optimism, may see robots as job-stealers, not saviors.

Fork in the Road: Tariffs’ False Promises vs. Tech’s Risky Bet

Trump’s tariff-driven vision—10–20% levies on imports, 60% on Chinese goods—promises to revive manufacturing by making domestic production cheaper. “Jobs and factories will come roaring back,” he declared in April 2025. But economists are skeptical. The National Association of Manufacturers estimates tariffs cost $40 billion annually, disrupting supply chains and raising consumer prices. Goldman Sachs notes the U.S.’s deep import reliance—70% of semiconductor inputs from Asia—means factories can’t run without global inputs. Trump’s first-term tariffs, studies show, created negligible jobs while hiking costs.

Contrast this with Germany’s Industry 4.0 model, which subsidizes automation for small and medium-sized enterprises (SMEs), boosting productivity while retraining workers. Since 2011, Germany’s €200 million annual investment has helped SMEs, which employ 60% of U.S. manufacturing workers (NAM, 2024), adopt robots. The result? A 20% productivity gain and a 4% unemployment rate, per OECD data. Alternatively, human-centric solutions—like apprenticeships or wage subsidies—could fill jobs and raise satisfaction but struggle against high labor costs and cultural stigma.

The U.S. faces a choice: double down on protectionism, hoping tariffs force reshoring, or embrace automation with guardrails to protect workers. The former risks economic disruption; the latter, social unrest if mishandled.

Charting the Future: Can Robots Rebuild Without Ruining Lives?

To harness robotics while safeguarding workers, the U.S. must blend innovation with empathy. Here are five policy recommendations, ranked by feasibility and impact:

- Subsidize SME Automation (High Feasibility, High Impact): Offer tax credits covering 30–50% of robot costs for SMEs, modeled on the CHIPS Act’s $39 billion for semiconductors. This democratizes access, as SMEs employ 60% of manufacturing workers, and boosts competitiveness without tariff chaos.

- Scale Retraining Programs (High Feasibility, High Impact): Invest $10 billion over five years in robotics and AI training via community colleges and apprenticeships, like Siemens’ U.S. centers, which upskill 1,000 workers annually. This addresses skill gaps (60% of manufacturers lack skilled workers, NAM) and mitigates displacement, easing financial anxiety.

- Build Domestic Robot Supply Chains (Moderate Feasibility, High Impact): Allocate $5 billion for public-private partnerships to produce robot components domestically, reducing import reliance. The Defense Department’s $2 billion Microelectronics Commons (2023) offers a blueprint.

- Promote Collaborative Robots (High Feasibility, Moderate Impact): Fund cobots ($20,000–$50,000 each) that work alongside humans, increasing productivity 20% in SMEs (Universal Robots, 2023). This preserves jobs while improving flexibility, addressing Pew’s 45% dissatisfaction rate.

- Worker Transition Fund (Moderate Feasibility, Moderate Impact): Tax automation profits 1% to finance wage subsidies and retraining for displaced workers, akin to South Korea’s 2024 proposal. This reduces union resistance and financial stress but faces political hurdles.

These steps could revive industrial towns by creating high-skill jobs—500,000 by 2030, with median wages up 15% to $50,000, per BLS projections—while boosting U.S. manufacturing’s global share from 15% to 20% (World Bank). But they demand moral clarity: automation must serve workers, not replace them. Rural anxiety, not Silicon Valley’s techno-utopianism, should guide policy.

Questions to Ignite the Fight

- Is America’s real crisis not vanishing jobs, but its stubborn resistance to a high-tech manufacturing future?

- Can robots rebuild the middle class, or will they cement a divided economy of coders and gig workers?

- If automation resurrects factories but hollows out industrial towns, have Americans triumphed—or failed?

Automation is not the future—it’s the present. And what America chooses to do with it will write the story of its next century. Youngstown and Austin are more than cities. They’re test sites for America’s courage.

- ₱75 Million Heist: Cops Gone Full Bandit

- ₱6.7-Trillion Temptation: The Great Pork Zombie Revival and the “Collegial” Vote-Buying Circus

- ₱1.9 Billion for 382 Units and a Rooftop Pool: Poverty Solved, Next Problem Please

- ₱1.35 Trillion for Education: Bigger Budget, Same Old Thieves’ Banquet

- ₱1 Billion Congressional Seat? Sorry, Sold Out Na Raw — Si Bello Raw Ang Hindi Bumili

- “We Will Take Care of It”: Bersamin’s P52-Billion Love Letter to Corruption

- “Skewed Narrative”? More Like Skewered Taxpayers!

- “Scared to Sign Vouchers” Is Now Official GDP Policy – Welcome to the Philippines’ Permanent Paralysis Economy

- “Robbed by Restitution?” Curlee Discaya’s Tears Over Returning What He Never Earned

- “My Brother the President Is a Junkie”: A Marcos Family Reunion Special

- “Mapipilitan Akong Gawing Zero”: The Day Senator Rodante Marcoleta Confessed to Perjury on National Television and Thought We’d Clap for the Creativity

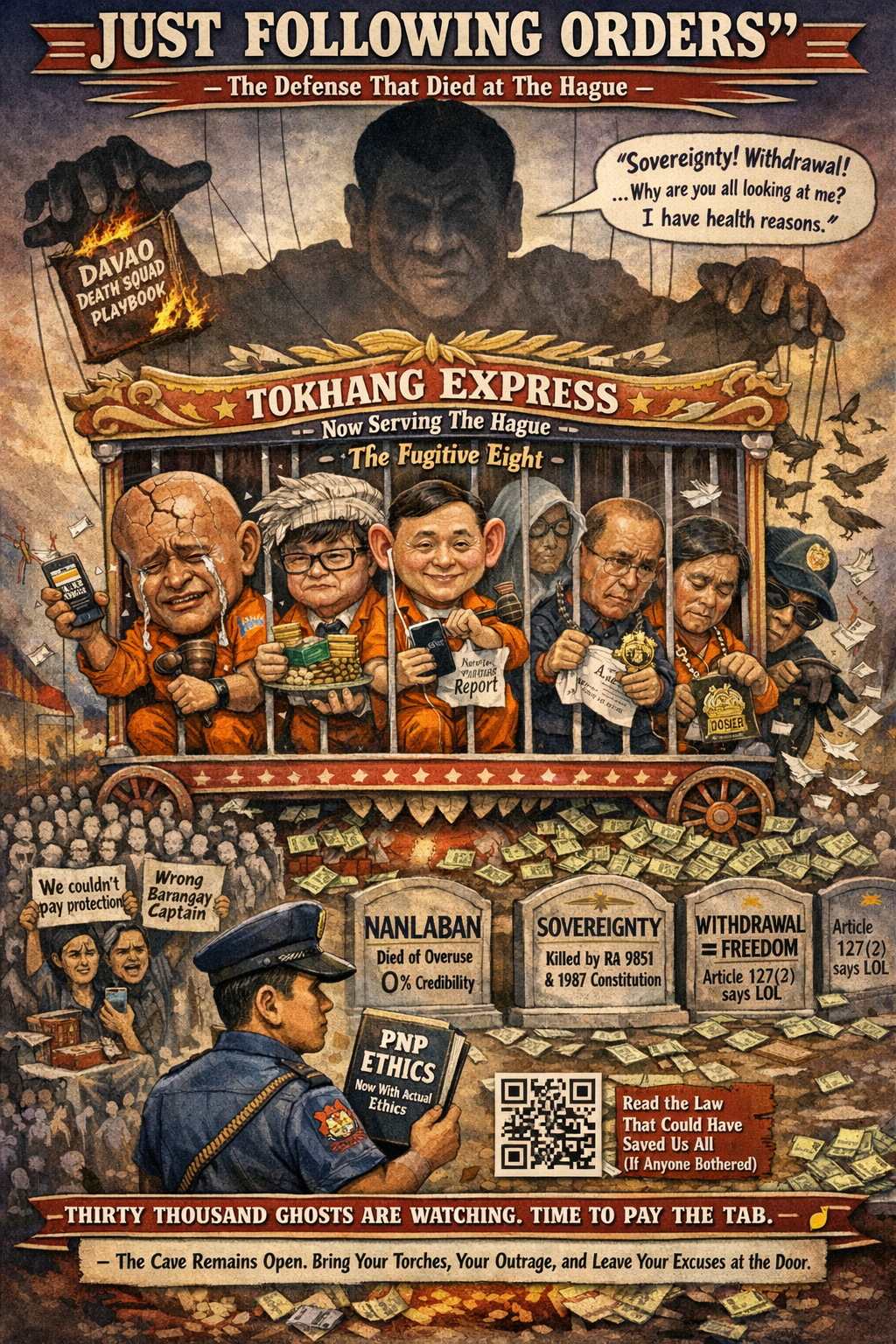

- “Just Following Orders” Is Dead: How the Hague Just Turned Tokhang’s Finest Into International Fugitives

Leave a comment